Water Treatment

Under general supervision, operates, maintains and repairs a wide variety of complex machinery and equipment in a water treatment plant and/or pumping station or related facility. Performs related duties as assigned.

Definition

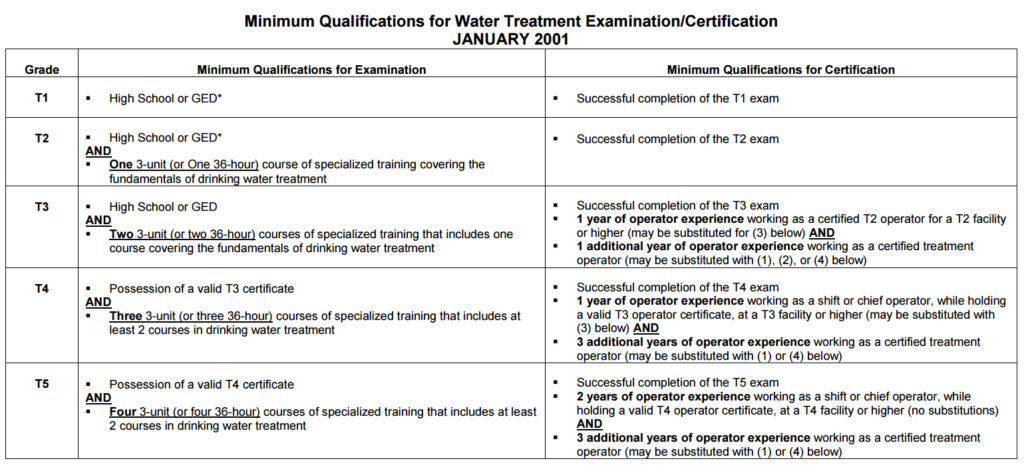

In 1998, the Federal Environmental Protection Agency established guidelines for operator certification. The state of California has five operator grades, T1-T5. A T1 certificate is the lowest grade and T5 is the highest. Progression through the grades requires a combination of specialized training courses and plant experience.

Specialized training courses can be obtained from a community college or correspondence courses through the Office of Water Programs at the California State University, Sacramento. Plant experience must be obtained by working or volunteering at a water utility.

Example Knowledge, Skills, and Abilities

Working knowledge of: The operation and maintenance of water treatment plants; methods and practices, including safety regulations pertaining to the work; water treatment and related equipment servicing , calibrating, and repair; mechanical, electrical, and hydraulic principles; principles and practices of standardized water quality tests; state and federal regulations governing the operation of a water treatment plant.

General knowledge of: Uses and principles of computerized electronic equipment in the collection, storage and interpretation of operational data related to water treatment and distribution; the operation and maintenance of water distribution systems; inventory control of water treatment chemicals, fuel and supplies; routine operating report generation; current technological developments in water treatment, distribution and water quality. Skill in: Operating water treatment system equipment including automatic control devices and plant equipment; maintaining safe and reliable water supply to customers; servicing, repairing and calibrating plant equipment; operating without immediate or detailed supervision.

Ability to: Establish and maintain effective working relationships; communicate effectively, verbally and in writing; prepare clear and concise reports; recognize unusual, inefficient, or dangerous operating conditions and take appropriate action; accurately read, interpret and record data from gauges, meters and a SCADA system; read and interpret schematic drawings showing plant piping, alarms, mechanical, electrical controls, valves, and related instrumentation; observe, inspect, analyze system equipment and facilities; and compile, evaluate and analyze operational data and information and recommend or take appropriate actions; and learn advanced SCADA System techniques and complex analyses of water treatment system requirements; to operate and maintain the distribution system on an emergency or as needed basis.

Click here to download this chart (pdf) >

Example Experience and Training

Four years journey-level Operator and/or Stationary Engineer experience in the maintenance, repair and operation of a variety of mechanical and electrical pumping and related plant machinery of a water or wastewater treatment plant; or four years journey-level experience as a Marine Engineer performing duties in the areas of maintenance, repair and operation of a variety of mechanical and electrical pumping and related machinery; or completion of a recognized four year Stationary Engineer apprenticeship program.

Example Monthly Salary Range

- Apprentice/Trainee $5,200 to $6,400

- Journey-level $6,300 to $7,500

- Supervisory $8,000 to $9,500

Source: BAYWORK